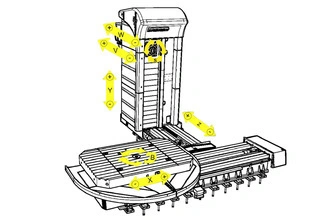

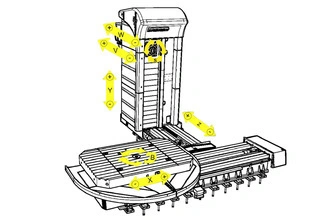

Most popular FERMAT table-type horizontal boring mill, for high-performance. This FERMAT Horizontal Boring mill is designed with both RAM & Spindle for maximum reach and ridgidity This FERMAT Machine allows for h maximum utilization of accessories and automatic milling heads for efficient machining of workpieces of up to 20 tons.

6" Spindle diameter,

32" spindles travel

27.56" Ram Stroke

Powerful and precise milling, coordinate drilling, boring, and threading. Extremely versatile series of table-type horizontal boring mills, fully compatible with a wide range of accessories and automatic milling heads.

Fermat WFT 15R

Specifications:

X / Y / Z / W (axes travels)

157.4” / 98.4” / 78.7” / 27.5”/ 31.4”

4 000 / 2 500 / 2 000 / 700 /800 mm

Spindle Diameter..................................................... 150 mm, 5.9”

Spindle Speed.......................................................... 2,800 RPM,

Spindle Torque......................................................... 2,210 Nm / 1,630 ft-force-lb

Spindle Main Motor Power (S1) Fanuc.................. 37 kW / 50 hp

Spindle Taper........................................................... CAT 50 (SK 50 Taper)

CNC Control Systems:

Fanuc 31iB,

Siemens Sinumeric,

Heidenhain

Linear Scales............................................................ Heidenhain

Optical absolute X, Y, Z

Headstock V130

Spindle Taper............................................................. SK50

Tool Standard............................................................ CAT 50

Dimensions of the Spindlebox.................................. 15.74“ x 15.74“

Working Range of the Axes

Max. feed rate All Axes.............................................. 314.96 in/min

Max. Rapid Feed X Axis, Y Axis................................. 472.44 in/min

Max. Rapid Feed Z Axis, W Axis................................ 393.7 in/min

Max. Axial Force X Axis, Y Axis................................. 5,620 lbf

Max. Axial Force Z Axis, W Axis................................ 6 294 lbf

Accuracy and Repeatability of the Positioning........ According to VDI/DGQ 3441

X, Y, Z Axes Ball Screw Diameter............................... 3.149“

W-axis Ball Screw Diameter....................................... 2.48“

Hydraulic and Pneumatic System

Nominal Pressure in the Hydraulic Aggregate/Max. Pressure... 1,450-1,595 psi

Nominal Pressure in the Lubrication Aggregate.......................... 435.11 psi

Tool Clamping Force...................................................................... 5,395 lbf

Tool Clamping System................................................................... Mechanical – Disk Springs

(Unclamped Hydraulically)

Electricity

Total Installed Load........................................................................ 96-1201kVA

Operating Voltage........................................................................... 3 x 400V

Operating Voltage Allowance......................................................... ± 5%

Control Low Voltage........................................................................ 24V

Operating Voltage Frequency......................................................... 50 / 60Hz

Max. Noise Level at Operator’s Location LAeq

(at 80% RPM and Feed Rate)......................................................... 80dB

Max. Noise Level at Operator’s Location....................................... 80dB

Operating Climate............................................................................ Normal

Spindle Drive..................................................................................... a.c. asynchronous

Feed Drive......................................................................................... a.c. synchronous

Rotary Table Options (mm):

*T10*

1200x1200, 1200x1400, 1400x1600, 1600x1600, 1400x1800, 1600x1800

*T20*

1600 x 1800/1800 x 2200/1800 x 2600/2000 x 2400/2500 x 2500/2000 x 3000

*T25/50*

2000 x 2000, 2000 x 2500, 2500 x 2500, 2500 x 3000, 3000 x 3000, 3000 x 3500, 3500 x 3500, 2500 x 5000

Coolant System: 900 l reservoir

High Pressure

Max. 1 019 psi output pressure of the unit (coolant through spindle)

Low Pressure

Max. 89 psi output pressure of the unit (outside coolant system)

Chip Conveyor: Belt Type with Coolant Return Pump included

Tool Changer: 40 Tools

Chain Magazine

Horizontal Tool Change

Service: Remote Diagnostics

Prepared in the Electric Switchboard (the Connection is Carried Out by the Customer)

A Warranty service must

Work Lighting: In the Operator’s Cabin,

Spotlight on the Cabin,

Upper Lighting from the Upper Cover of the Column Base (to be discussed)

Operator’s Safety: Stationary Operator’s Safety Cabin

*Standard Accessories*

Air-conditioned Electric Switchboard

UL-Certified execution

Automatic System of Slide Guideways Lubrication

Hydraulic Unit

Cooling Unit for Thermal Stabilization of Spindle Bearings

We use cookies to improve your experience. Privacy Policy.