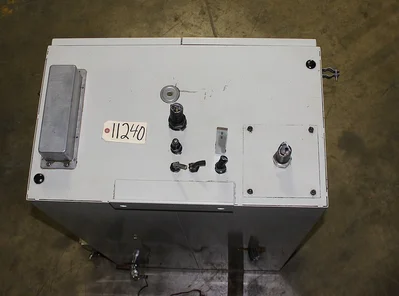

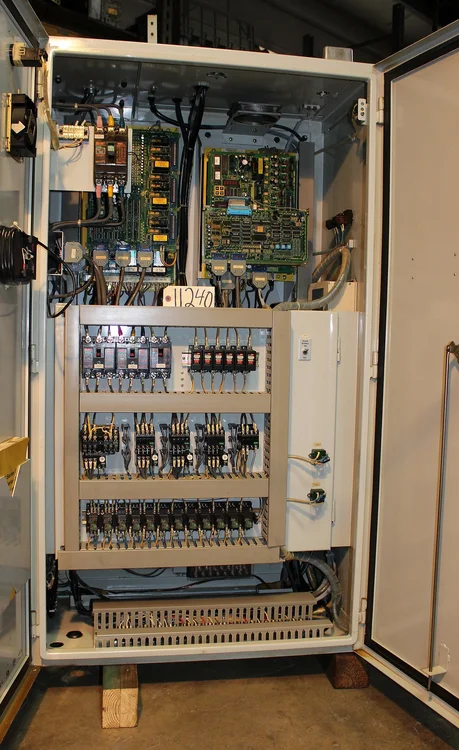

GE FANUC OM CNC Control Panel, reclaimed, used from a running machine at decommissioning, available. Model 0M, year 1996, shipped skidded, strapped, and wrapped. Ideal for those seeking quality N/C & CNC controls supplies.

G.E. FANUC OM CNC CONTROL, COMPLETE PANNEL RECLAIMED FROM RUNNING MACHINE AT TIME OF DECOMMISIONING.

SHIPPED SKIDDED, STRAPPED, AND WRAPPED

Key Features

Reliability: The 0M control is widely recognized for its robust and reliable performance, with many units still in use today.

Programming: It utilizes standard Fanuc G-code programming and supports features like cutter compensation (G41, G42), multiple coordinate systems (G54-G59), and various canned cycles for operations like drilling.

Components: The system is known for using AC servo motors that can incorporate an electronic absolute detector, which eliminates the need for a zero return procedure after every power-off cycle.

Customization: It allowed for a high degree of customization through its internal Programmable Machine Control (PMC), enabling machine builders to incorporate specific functions, such as Automatic Tool Changers (ATC).

Interface: The control panel typically included a CRT (Cathode Ray Tube) display and MDI (Manual Data Input) panel for operation and programming.

Operation and Maintenance

Parameter Management: The system relies heavily on parameters stored in memory, which are backed up by batteries. Proper procedures are required for backing up and restoring these parameters, especially during battery replacement, to avoid losing machine settings.

Troubleshooting: Common issues often involve setting the machine's home or reference position (zero return) and managing alarms, which usually requires specific parameter adjustments (e.g., parameter 1815).

Connectivity: The 0M control supports data transfer (DNC - Direct Numerical Control) from a PC via serial communication (RS-232), using specific parameter settings and a null modem cable.

We use cookies to improve your experience. Privacy Policy.