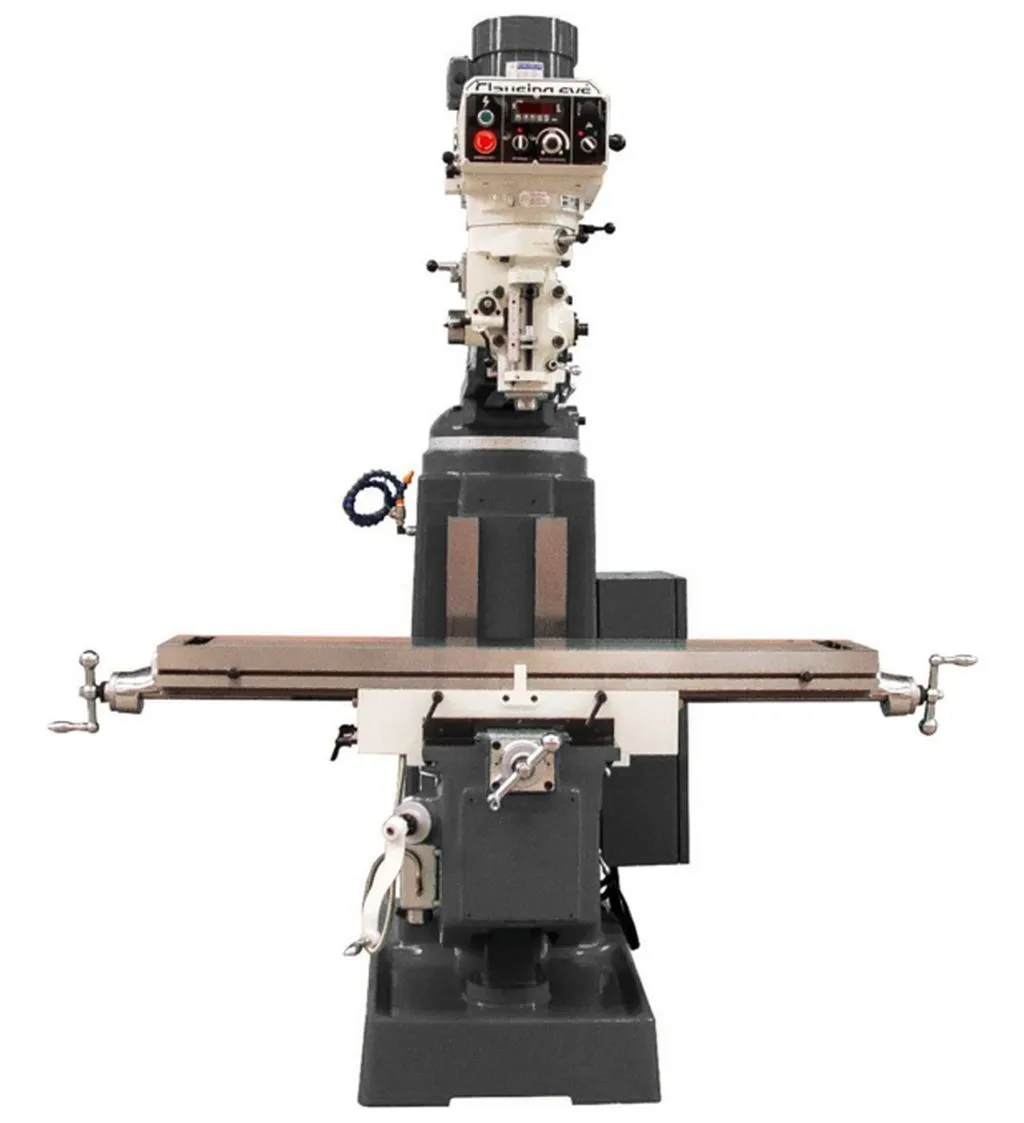

Explore precision and power with the new Clausing 400EVS30 Knee Mill. Featuring a 10"x50" table, electronic variable speed up to 5000 RPM, and a robust 3 hp motor. Ideal for vertical milling tasks with hardened and ground surfaces for superior performance.

Machine Style..........Knee Mill

Spindle Speed Control..........Electronic Variable Speed

Spindle (Hp)..........3

Total Amp Draw @208V 3Ph..........11

Total Amp Draw @230V 3PH..........10

Total Amp Draw @460V 3Ph..........5

Table Size (inch)..........10 x 50

Number T-Slots..........3

T-Slot Width (inch)..........(.63)

T-Slot Center Distance (inch)..........2.48

Table Way Design..........Dovetail

Cross Feed Way Design..........Dovetail

Knee Way Design..........Dovetail

X Longitudinal Travel Manual (inch)..........35

Y Cross Travel Manual (inch)..........16

Knee Travel Manual (inch)..........16

Ram Travel Manual (inch)..........22

Variable Spindle Speed (rpm)..........50 – 5000

Variable Spindle Speed Low Range (rpm)..........50 – 500

Variable Spindle Speed High Range (rpm)..........500 – 5000

Spindle Taper..........NMTB 30

Spindle quill Travel (inch)..........5

Quill Feed (in/rev)..........(.00157/.00315/.006)

Quill Diameter (inch)..........3.28

Column Turret Diameter (inch)..........15.75

Knee Width (inch)..........13.75

Column Bearing Length (inch)..........17.72

Saddle/Table Bearing Length (inch)..........20.08

Ram/Turret Bearing Length (inch)..........17.72

Ram Length (inch)..........32.75

Table Load (lbs.)..........665

Machine Weight (lbs.)..........2,640

Voltage Required..........230/460

Phase..........3

Machine Foot Print (LxWxH) (inch)..........102 x 78 x 88.6

Shipping Weight (lbs.)..........3,040

Machine Features:

Electronic variable speed with inverter drive

10” X 50” Table surface

Meehanite Castings for superior rigidity and wear resistance

Hardened and Ground X,Y,&Z ways

X/Y ways coated with Turcite B for excellent wear resistance

Column and Knee way covers

Ground T-slots to provide reference edge for workpiece positioning

Hardened and ground table surface, and spindle

Chromed and ground quill

Hardened and ground X and Y axis leadscrews with Nickel Phosphorous treatment and double nuts for easy backlash adjustments

ABEC7/CP4 Spindle bearings

Coolant System w/pump and switch

Articulating head for compound angles 90 degree left and right 45 degree up and down by worm gear

Lever operated manual rapid quill movement

Hand wheel for fine quill feed

Adjustable automatic feed disengagement for quill feed

Micrometer depth stop for quill

Reversing switch for clockwise or counter clockwise operation of spindle

Hand operated spindle brake with auto power off

One shot way lube system

A one year warranty backed by Clausing Service Center dedicated to support our customers with parts and service

We use cookies to improve your experience. Privacy Policy.