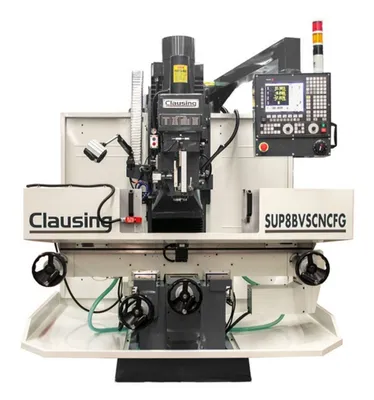

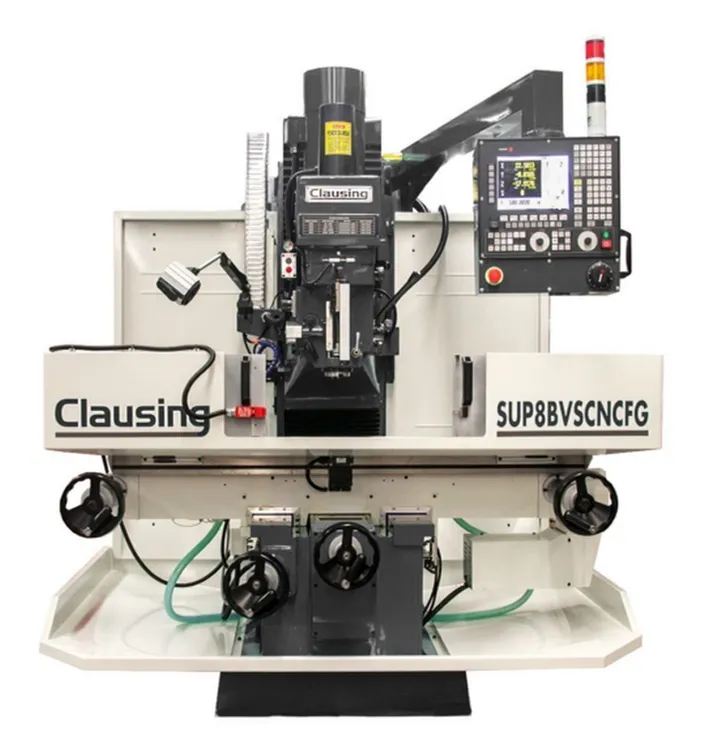

Explore unmatched precision with the Clausing SUP16BVVCNC CNC Bed Mill. Featuring a 19.68" x 86.6" table, 7.5 hp motor, electronic spindle speed up to 8,000 RPM, and robust Fanuc Oi Control, it's engineered for high-performance tasks.

Machine Style..........CNC Super Bed Mill

Spindle Speed Control.................Electronic Variable Speed

Number of Controlled Axes........3 (X, Y, Z-Column)

Manual Quill Scale W-Axis..........Yes (synchronized)

Spindle Motor Horsepower.........7.5

Table Size (inch)..........................19.68 x 86.6

Table Load Capacity (lbs.)..........2,500

T-Slot Width (in)...........................(.630)

T-Slot Center Distance (inch).......3.75

Number T-Slots..........3

Table Way Design..........Dovetail

Cross Feed Way Design..........Square

Column Way Design..........Square

X – Longitudinal Travel Manual (inch).....62.99

Y – Cross Travel Manual (inch)................27.55

Z – Column Travel Manual (inch).............27.55

Programmed Feed Rate X,Y (in/min).......0 – 29.53

Rapid Feed X,Y (in/min)..........472

Programmed Feed Rate Z (in/min)...........0 - 29.53

Rapid Feed Z (in/min)..........472

Variable Spindle Speed (rpm)..........0 – 8000

Spindle Taper..........CAT 40

Length of Saddle on Bed (inch)..........54

Width Across Bed Ways (inch)..........23

Spindle Nose to Table (inch)..........4.7 – 32.28

Center of Spindle to Column Ways (inch)..........26.37

Floor to Table Surface (inch)..........35

Voltage Required..........230 or 460 (w/transformer)

Phase..........3

Machine Weight (lbs.)..........9,900

Machine Foot Print (WxDxH) (inch)..........126.8 x 99.6 x 114.6

Shipping Weight (lbs.)..........10,900

Machine Features:

Fanuc Oi Control

C5 double nut X,Y,Z axes 1.26” diameter ballscrew

Linear position feedback X,Y, Z-Column

Powerful 7.5 Hp main spindle drive motor

Electronic inverter variable spindle speed

Hardened and ground spindle with CAT 40 spindle taper

P4 Angular contact spindle bearings limit temperature variations

Hardened and ground table surface with ground t-slots for reference edges

Hardened and ground dovetail ways X axis, hardened and ground square ways Y and Z axis

“ Turcite B” coating on saddle X,Y,Z axes ways

1:2 Ratio timing belt boxes X, Y, Z axes for increased feed torque

Hardened and ground C5 double nut on X, Y, Z axes provide high precision movement

High grade castings for superior rigidity and wear resistance

Stainless steel Y, Z axis way covers

Automatic lubrication with alarm

Halogen worklight

Coolant system with pump

Optional 16 or 20 tool changer

Head and Table guards

Optional full guarding

A one year warranty backed by Clausing Service Center dedicated to support our customers with parts and service

We use cookies to improve your experience. Privacy Policy.