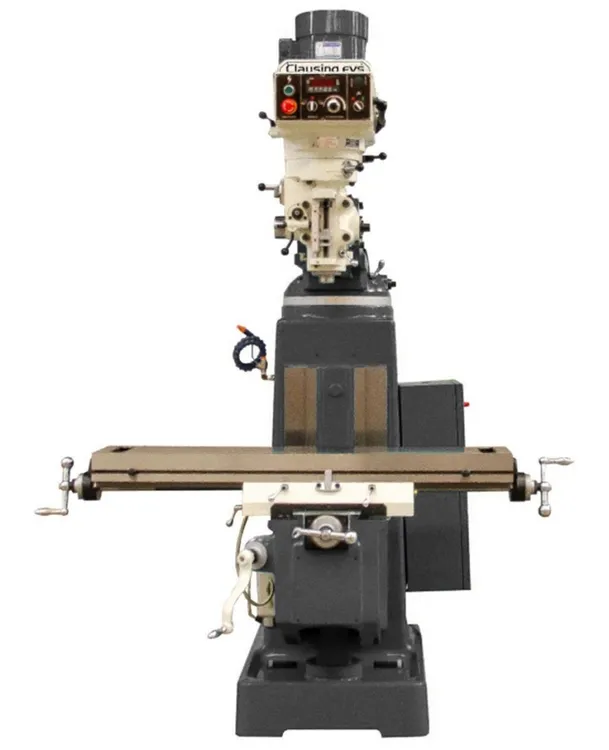

Clausing 2EVS08 Knee Mill offers precision with a 9"x49" table, 38.2" longitudinal travel, and R8 spindle taper. Features electronic variable speed, hardened X/Y/Z ways, and a 5" quill travel. Equipped with coolant system and one-shot way lube system.

Specifications:

• Machine Style..........Knee Mill

• Spindle Speed Control..........Electronic Variable Speed

• Spindle (Hp)..........3

• Total Amp Draw @208V 3Ph..........11

• Total Amp Draw @230V 3PH..........10

• Total Amp Draw @460V 3Ph..........5

• Table Size (inch)..........9 x 49

• Number T-Slots..........3

• T-Slot Width (inch)..........(.638)

• T-Slot Center Distance (inch)..........2.08

• Table Way Design..........Dovetail

• Cross Feed Way Design..........Dovetail

• Knee Way Design..........Dovetail

• X Longitudinal Travel Manual (inch)..........38.2

• Y Cross Travel Manual (inch)..........14.2

• Knee Travel Manual (inch)..........15

• Ram Travel Manual (inch)..........18.5

• Variable Spindle Speed (rpm)..........60 – 4300

• Variable Spindle Speed Low Range (rpm)..........60 – 500

• Variable Spindle Speed High Range (rpm)..........550 – 4300

• Spindle Taper..........R8

• Spindle quill Travel (inch)..........5

• Quill Feed (in/rev)..........(.0015/.0031/.006)

• Quill Diameter (inch)..........3.38

• Column Turret Diameter (inch)..........14.96

• Knee Width (inch)..........11.42

• Column Bearing Length (inch)..........16.54

• Saddle/Table Bearing Length (inch)..........19.88

• Ram/Turret Bearing Length (inch)..........16.14

• Ram Length (inch)..........28.94

• Table Load (lbs.)..........665

• Machine Weight (lbs.)..........2,100

• Voltage Required..........230/460

• Phase..........3

• Machine Foot Print (LxWxH) (inch)..........99 x 66 x 88.6

• Shipping Weight (lbs.)..........2,500

Machine Features:

• Electronic variable speed with inverter drive

• 9 X 49″ Table surface

• Meehanite Castings for superior rigidity and wear resistance

• Hardened and Ground X,Y,&;Z ways

• X/Y ways coated with Turcite B for excellent wear resistance

• Column and Knee way covers

• Ground T-slots to provide reference edge for workpiece positioning

• Hardened and ground table surface, and spindle

• Chromed and ground quill

• Chromed and double nut leadscrews for backlash compensation

• ABEC7/CP4 Spindle bearings

• Coolant System w/pump and switch

• Articulating head for compound angles 90 degree left and right 45 degree up and down by worm gear

• Lever operated manual rapid quill movement

• Hand wheel for fine quill feed

• Adjustable automatic feed disengagement for quill feed

• Micrometer depth stop for quill

• Reversing switch for clockwise or counter clockwise operation of spindle

• Hand operated spindle brake

• One shot way lube system

• A one year warranty backed by Clausing Service Center dedicated to support our customers with parts and service

We use cookies to improve your experience. Privacy Policy.