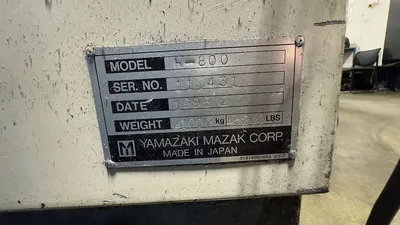

Optimize your production capabilities with the MAZAK MAZATECH H-800, a powerful horizontal machining center from 1995. Features include 49"x39"x33" travels, 35 hp spindle, 4,5000 RPM, dual-pallet changer, and a user-friendly Mazatrol M-Plus control.

GENERAL SPECIFICATIONS

Pallet Size / Number of Pallets: 31.5" x 31.5"/2 plts

Table Load Capacity: 4,840 lbs

Table Indexing: 1 Degree Index

X-Axis Travel: 49.21"

Y-Axis Travel: 39.37"

Z-Axis Travel: 33.46"

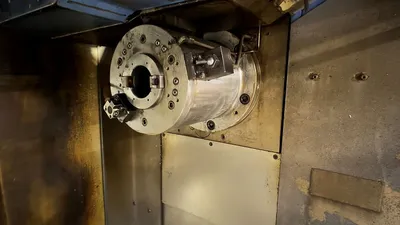

Spindle Nose: CAT # 50

Spindle Speed: 22 - 15,000 RPM

Spindle Motor: 35 HP

Spindle Center to Tabletop: 1.97" - 41.34""

Maximum pallet load capacity: 4,840 lbs (2,200 kg).

Tool Magazine Capacity: 40 Position ATC

Max. Tool Diameter: 10.24"

Rapid Traverse Rates: 708 IPM

Machine Dimensions: 217" x 129" x 126"

Machine Weight: 44,000 lbs

Dual-pallet changer: Allows for efficient, uninterrupted production by enabling one workpiece to be loaded or unloaded while another is being machined.

Mazatrol M-Plus control: This conversational CNC control system is designed to be user-friendly, minimizing the need for extensive G-code programming.

High-power spindle: The 35 HP motor and CAT #50 taper are designed for aggressive material removal and precision machining.

Spacious work envelope: The generous travel distances allow for the machining of large workpieces.

Automatic tool changer: The large-capacity ATC minimizes manual intervention and maximizes production uptime.

Customization options: Some machines were sold with additional features, such as a full rotary 4th axis, through-spindle coolant, or a Renishaw probe.

We use cookies to improve your experience. Privacy Policy.