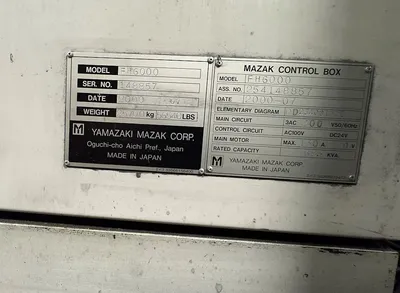

MAZAK MAZATECH FH-6000 horizontal machining center from 2000 with 4-axis, 40 hp, and 10,000 RPM. Features CAT #50 taper, 40-tool ATC, dual chip conveyors, and Mazatrol Fusion 640M control. Ideal for efficient multi-machine production setups.

Machine configuration: 4-axis Horizontal Machining Center.

CNC control: Mazatrol Fusion 640M, which supports both Mazatrol and EIA/ISO programming languages.

Approximate weight: 41,226 lbs, depending on options.

Dimensions: Approximately 146" x 250" x 125".

Spindle and tool system

Spindle speed: 7,000 to 10,000 RPM, depending on configuration.

Spindle motor: 40 HP.

Spindle taper: CAT #50.

Automatic Tool Changer (ATC): Magazine capacity of 40, 80, or 320 tools, depending on the machine's configuration.

Tool change time: Approximately 1.8 seconds (tool-to-tool) and 5 seconds (chip-to-chip).

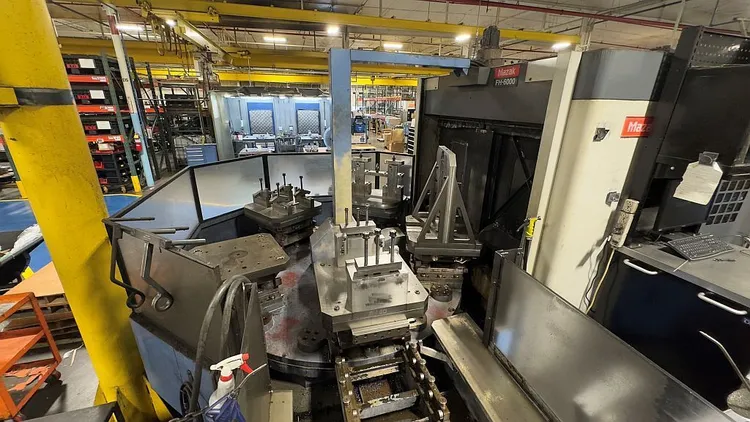

Pallets and work area

Pallet size: 19.69" x 19.69" (500 mm x 500 mm).

Pallet system: Often equipped with a two-pallet changer with T-slots. Can also be integrated into a larger Flexible Manufacturing System (FMS) with a Palletech system.

Maximum table load: Up to 2,200 lbs.

Indexing: Pallets can be indexed in 1-degree increments.

Maximum workpiece dimensions:

Diameter: 36.0".

Height: 40.0".

Travel and feed rates

X-axis travel: 31.5".

Y-axis travel: 31.5".

Z-axis travel: 34.7".

Rapid traverse rate: 1,575 IPM.

Maximum programmable feedrate: 1,575 IPM.

Notable features

Coolant system: Includes a coolant-thru-spindle feature.

Chip management: Comes equipped with dual rear-discharge chip conveyors.

Integrated systems: Can be configured with a Mazak Palletech System for automated, multi-machine production.

Monitoring and recovery: Includes tool life monitoring, breakage recovery, and length measurement.

We use cookies to improve your experience. Privacy Policy.