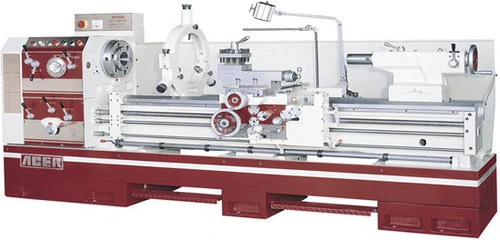

Experience precision with the new ACER Dynamic-2980G Precision Engine Lathe. Features a 29.125" swing, 80" centers, and 4.125" spindle bore, powered by a 15 HP motor with 12 speeds up to 1,200 RPM, ensuring exceptional performance for diverse machining tasks.

ACER Dynamic Lathe 2980G

General Capacity:

• Center height .......... 14-3/4"

• Swing over bed .......... 29-1/8"

• Swing over gap (Gap type only) .......... 37-25/32"

• Swing over cross slide .......... 20-1/2"

• Distance between centers .......... 80"

Main Spindle:

• Spindle nose .......... ASA 1-11 or D1-11

• Spindle bore diameter .......... 4-1/8"

• Type of spindle nose .......... 108 x 1:12

• Taper of center .......... MT.# 5

• Spindle speeds .......... 25 - 1200 rpm (12 steps)

Carriage:

• Cross slide travel .......... 18-1/4"

• Compound rest travel .......... 9"

• Max. size cutting tool .......... 1" x 1"

Tailstock:

• Spindle diameter .......... 3-1/32"

• Spindle travel .......... 7"

• Taper of center .......... MT.# 5

Bed:

• Bed length .......... 122"

• Bed width .......... 16-1/2"

• Width of gap .......... 20-1/4"

Threading & Feeding:

• System .......... Inch/Metric

• Pitch of leadscrew .......... 1-1/2" Ø, 4 TPI

• Metric pitch threads .......... 0.5 - 14mm/pitch (31 kinds)

• Inch pitch threads .......... 2 - 56 TPI (45 kinds)

• Module pitch threads .......... 0.25 - 7 M.P. (23 kinds)

• Diametral pitch threads .......... 4 - 112 D.P. (43 kinds)

• Range of longitudinal feeds .......... 0.0012 - 0.0287"/rev. 0.03 - 0.73mm/rev.

• Range of cross feeds .......... 0.0004 - 0.0118"/rev. 0.01 - 0.03mm/rev.

Power:

• Main drive motor .......... 15 HP

• Rapid traverse motor .......... 1/2 HP (optional)

• Coolant pump motor .......... 1/8 HP

Dimensions:

• Floor Dimension .......... 129" x 50"

• Net Weight .......... 7,680 lbs

• Gross Weight .......... 9,190 lbs

• Packing Dimension .......... 144.5" x 50" x 74"

***NOTE! The manufacturer reserves the right to modify the design, specifications, mechanisms, etc. to improve the performances of the machines without notice. All specifications shown above are for reference only.

Machine Features:

• Ampere meter for indicating power consumption.

• Magnetic multiple-disc clutches in the headstock are used for efficient starting and reversing the spindle.

• Manual jog button.

• 12 speeds range from 25 to 1,200 RPM.

• Oil flood indicator.

• One of the outside gears on the gear box is designed with a safety ring to protect it from damage.

• Optional 2nd starting lever.

• Drip-proof 15 HP spindle motor.

• Magnetic disc brake with foot pedal allows for rapid control of the spindle rotation.

• Hardened & ground bedways at Rockwell C 55°.

• Electro-trochoid pump forces lubrication oil to all running parts outside of the headstock.

• Handwheel with direct inch/metric reading micro-collar.

• Precision ground cross slideways.

• Saddle-lock device for heavy cutting.

• Rapid four directional travel.

• Safety clutched and longitudinal lead screw.

• 4 TPI and oil bathed longintudinal lead screw.

• Oil level indicator.

• Forward/stop/reverse lever with safety device.

• Multi-position length stop.

• Removable chip pan.

• Machine bed with FC-30 casting iron.

Standard accessories:

• 20" D1-11 four jaw chuck

• 20" face plate

• 16" drive plate

• Built-in coolant system

• 4-way tool post

• Longitudinal carriage stop

• Chuck guard w/ emergency stop

• Halogen work light

• 12" adaptor plate

• Toolbox w/ tools

• Follow rest

• One steady rest (3.1"-9.5" long tip, bearing type) (7.8"-14.5" short tip, bearing type)

• Followable splash guard (34" wide) (60", 80" w/ full length splash guard)

Optional accessories:

• 24" 4-jaw independent chuck (D1-11) w/ direct mount

• Follow rest (0.4"-3.4")

• Face plate (24")

• "Aloris" tool post & 4 holders (#5-BS)

• "Aloris" tool post & 6 holders (#5-SET)

• "Dorian" tool post with holders (SD50DA-TS)

• Micrometer stop

• Six position carriage stop

• Taper turning attachment

• Installation fee for taper turning attachment

• "Newall" 2-axis DRO (18" x 80" travel)

• "Magnescale" 2-axis DRO (18" x 80")

• Installation fee for DRO

We use cookies to improve your experience. Privacy Policy.